Curvic Coupling was developed by Gleason company from USA in 1942 and was registered for Curvic by the Gleason company.

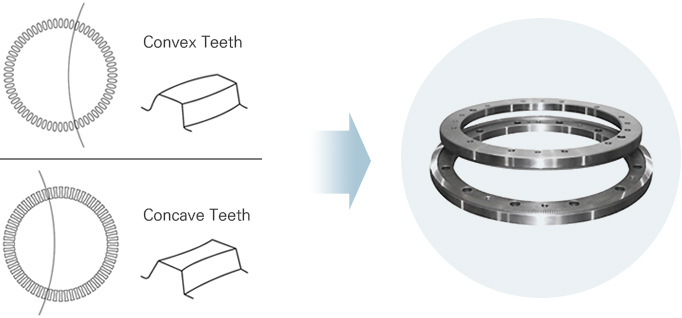

Curvic coupling types include fixed type, half size type and interlock type.

The most commonly used for double precision division is fixed type.

The Fixed Curvic Coupling is used extensively in the construction of built-up turbine and compressor rotors for aircraft and industrial gas or steam turbine engines.

In the 4th Japan’s machine tools exhibition in 1968, Curvic Coupling got into sportlight an important element as indexing positioning instrument.

By rapid developing of NC and CNC machine tool, Curvic has become representative of high accuracy and super rigidity.

Since then, we, Duckbo Tech. Co., Ltd. have begun to develop and produce by different processing method.

| Classification | 2PCC | 3PCC | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

3 0 |

5 0 |

6 3 |

8 0 |

1 0 0 |

1 2 0 |

1 4 0 |

1 6 0 |

1 8 0 |

2 0 0 |

2 1 0 |

2 5 0 |

2 8 0 |

3 2 0 |

3 6 0 |

4 0 0 |

4 2 0 |

4 5 0 |

5 2 0 |

6 0 0 |

7 0 0 |

8 0 0 |

9 0 0 |

1 0 0 0 |

1 1 0 0 |

1 2 0 0 |

1 3 0 0 |

1 1 0 |

1 3 5 |

1 6 5 |

2 0 0 |

2 3 0 |

2 5 0 |

2 7 0 |

3 3 5 |

4 2 5 |

5 4 0 |

6 3 0 |

6 2 0 |

| 20 | |||||||||||||||||||||||||||||||||||||||

| 24 | |||||||||||||||||||||||||||||||||||||||

| 30 | |||||||||||||||||||||||||||||||||||||||

| 32 | |||||||||||||||||||||||||||||||||||||||

| 36 | |||||||||||||||||||||||||||||||||||||||

| 40 | |||||||||||||||||||||||||||||||||||||||

| 48 | |||||||||||||||||||||||||||||||||||||||

| 60 | |||||||||||||||||||||||||||||||||||||||

| 72 | |||||||||||||||||||||||||||||||||||||||

| 360 | |||||||||||||||||||||||||||||||||||||||

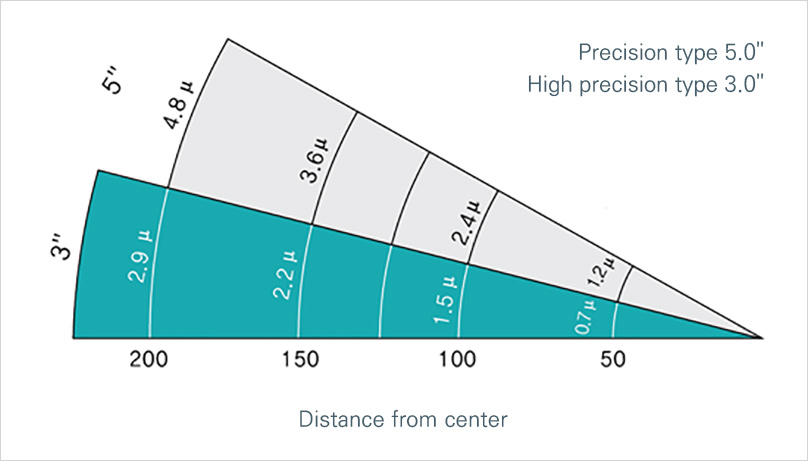

| Classification | Pricision type | Note | ||

|---|---|---|---|---|

| A | Tooth contact | At the number of teeth (BN) |

more than 80% |

"Tooth mating state is bringing into contact with the standard master coupling. The standard tooth contact length should be above 50% of tooth length.

|

| At the face width (BN) |

more than 50% | |||

| B | Runout | Runout on top face At the number of teeth | 0.02 | The run out is checked by light mating with master curvic coupilng. |

| Runout of outside diameter | 0.02 | |||

| C | Stacking distance (S, D) | ±0.10 | The combined thickness of mated convex and concave teeth is method as H3 in the standard dimension table. | |

| Indexing accuracy (accumulative) | less than 5 sec |  |

|---|---|---|

| Restoration accuracy | less than ±1.0 sec | |

| Same tooth mating location | ±0.01 | |

| Mutual Difference at same tooth mating location | ±0.01 |

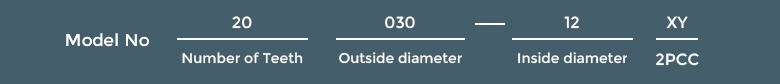

| No. | Model No | Out side dia meter |

Out side dia meter of Teeth |

Inside dia meter |

Num ber of teeth |

Teeth width | Tooth top from back face | Boss from back face | Stacking distance | Fixed bolt hole | Positioning pin hole | Withdraw bolt hole | Adden dum |

Allowable Misalign -ment |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of hole |

PCD | Hole diameter | Spot facing hole | Number of pin hole | PCD | Angle of hole | Hole diameter | Number of bolt hole |

PCD | Tap diameter |

|||||||||||||

| Diameter | Depth | ||||||||||||||||||||||

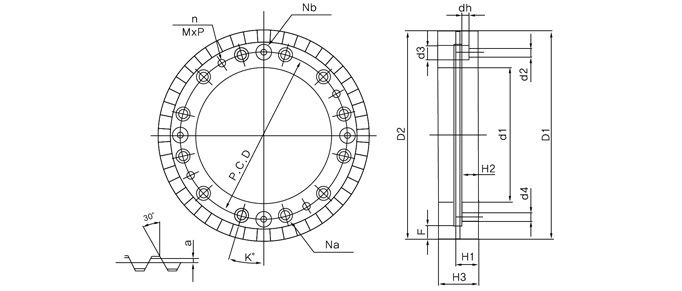

| D1 | D2 | d1 | N | F | H1 | H2 | H3 | Na | P.C.D | d2 | d3 | dh | Nb | P.C.D | K˚ | d4 | n | P.C.D | MxP | a | ±A | ||

| 1 | 20030-12XV | 30 | 29 | 12 | 20 | 3 | 7.30 | 5.5 | 14 | 4 | 20 | M5 | - | - | 2 | 19 | 45˚ | Φ2 마킹부 | 4 | 20 | M5x0.8 | 0.30 | 0.27 |

| 2 | 24050-22XV | 50 | 49 | 22 | 24 | 5 | 10.50 | 8.0 | 20 | 4 | 34 | M5 | 8.0 | 6.0 | 4 | 32 | 45˚ | Φ2 마킹부 | 4 | 34 | M5x0.8 | 0.50 | 0.42 |

| 3 | 20063-36XV | 63 | 62 | 36 | 20 | 6 | 12.80 | 10.0 | 24 | 6 | 48 | M5 | 8.0 | 6.8 | 4 | 44 | 30˚ | Φ2 마킹부 | 6 | 48 | M5x0.8 | 0.80 | 0.69 |

| 4 | 24063-36XV | 63 | 62 | 36 | 24 | 6 | 12.80 | 10.0 | 24 | 6 | 48 | M5 | 8.0 | 6.8 | 4 | 44 | 30˚ | Φ2 마킹부 | 6 | 48 | M5x0.8 | 0.80 | 0.69 |

| 5 | 20080-44XV | 80 | 79 | 44 | 20 | 8 | 15.30 | 12.0 | 29 | 6 | 60 | M8 | 11.0 | 8.8 | 4 | 55 | 30˚ | Φ2 마킹부 | 6 | 60 | M8x1.25 | 0.80 | 0.69 |

| 6 | 24080-44XV | 80 | 79 | 44 | 24 | 8 | 15.30 | 12.0 | 29 | 6 | 60 | M8 | 11.0 | 8.8 | 4 | 55 | 30˚ | Φ2 마킹부 | 6 | 60 | M8x1.25 | 0.80 | 0.69 |

| 7 | 20100-40XV | 100 | 98 | 40 | 20 | 9 | 18.37 | 14.0 | 34 | 6 | 60 | 6.6 | 11.0 | 6.0 | 3 | 60 | 30˚ | 8 | 2 | 60 | M8x1.25 | 1.37 | 1.22 |

| 8 | 30100-40XV | 100 | 98 | 40 | 30 | 7 | 18.30 | 14.0 | 34 | 6 | 60 | 6.6 | 11.0 | 6.0 | 3 | 60 | 30˚ | 8 | 2 | 60 | M8x1.25 | 1.30 | 1.15 |

| 9 | 24120-60XV | 120 | 118 | 60 | 24 | 8 | 18.30 | 14.0 | 34 | 6 | 80 | 6.6 | 11.0 | 6.0 | 3 | 80 | 30˚ | 8 | 2 | 80 | M8x1.25 | 1.30 | 1.15 |

| 10 | 30120-60XV | 120 | 118 | 60 | 30 | 7 | 18.56 | 14.0 | 34 | 6 | 80 | 6.6 | 11.0 | 6.0 | 3 | 80 | 30˚ | 8 | 2 | 80 | M8x1.25 | 1.56 | 1.39 |

| 11 | 32120-60XV | 120 | 118 | 60 | 32 | 11 | 18.46 | 14.0 | 34 | 6 | 82 | 6.6 | 11.0 | 6.0 | 3 | 82 | 30˚ | 8 | 2 | 82 | M8x1.25 | 1.46 | 1.30 |

| 12 | 24140-80XV | 140 | 138 | 80 | 24 | 9 | 18.59 | 14.0 | 34 | 6 | 100 | 6.6 | 11.0 | 6.0 | 3 | 100 | 30˚ | 8 | 2 | 100 | M8x1.25 | 1.59 | 1.42 |

| 13 | 36140-80XV | 140 | 138 | 80 | 36 | 11 | 18.52 | 14.0 | 34 | 6 | 100 | 6.6 | 11.0 | 6.0 | 3 | 100 | 30˚ | 8 | 2 | 100 | M8x1.25 | 1.52 | 1.36 |

| 14 | 40140-80XV | 140 | 138 | 80 | 40 | 11 | 18.37 | 14.0 | 34 | 6 | 100 | 6.6 | 11.0 | 6.0 | 3 | 100 | 30˚ | 8 | 2 | 100 | M8x1.25 | 1.37 | 1.22 |

| 15 | 24160-100XV | 160 | 158 | 100 | 24 | 9 | 21.73 | 16.5 | 40 | 8 | 118 | 9 | 14.0 | 8.0 | 3 | 118 | 22.5˚ | 10 | 2 | 118 | M8x1.25 | 1.73 | 1.54 |

| 16 | 36160-100XV | 160 | 158 | 100 | 36 | 9 | 21.73 | 16.5 | 40 | 8 | 118 | 9 | 14.0 | 8.0 | 3 | 118 | 22.5˚ | 10 | 2 | 118 | M8x1.25 | 1.73 | 1.54 |

| 17 | 40160-100XV | 160 | 158 | 100 | 40 | 9 | 21.56 | 16.5 | 40 | 8 | 118 | 9 | 14.0 | 8.0 | 3 | 118 | 22.5˚ | 10 | 2 | 118 | M8x1.25 | 1.56 | 1.39 |

| 18 | 24180-120XV | 180 | 178 | 120 | 24 | 9 | 21.61 | 16.5 | 40 | 8 | 140 | 9 | 14.0 | 8.0 | 3 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.61 | 1.44 |

| 19 | 36180-120XV | 180 | 178 | 120 | 36 | 9 | 21.37 | 16.5 | 40 | 8 | 140 | 9 | 14.0 | 8.0 | 3 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.37 | 1.22 |

| 20 | 40180-120XV | 180 | 178 | 120 | 40 | 9 | 21.76 | 16.5 | 40 | 8 | 140 | 9 | 14.0 | 8.0 | 3 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.76 | 1.57 |

| 21 | 24200-120XV | 200 | 198 | 120 | 24 | 9 | 21.63 | 16.5 | 40 | 8 | 150 | 9 | 14.0 | 8.0 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 1.63 | 1.45 |

| 22 | 36200-120XV | 200 | 198 | 120 | 36 | 11 | 21.52 | 16.5 | 40 | 8 | 150 | 9 | 14.0 | 8.0 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 1.52 | 1.36 |

| 23 | 40200-120XV | 200 | 198 | 120 | 40 | 9 | 21.37 | 16.5 | 40 | 8 | 150 | 9 | 14.0 | 8.0 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 1.37 | 1.22 |

| 24 | 72200-120XV | 200 | 198 | 120 | 72 | 9 | 20.99 | 16.5 | 40 | 8 | 150 | 9 | 14.0 | 8.0 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 0.99 | 0.89 |

| 25 | 360200-120XV | 200 | 198 | 120 | 360 | 5 | 20.20 | 16.5 | 40 | 8 | 150 | 9 | 14.0 | 8.0 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 0.20 | 0.17 |

| 26 | 24210-135XV | 210 | 208 | 135 | 24 | 12 | 21.71 | 16.5 | 40 | 12 | 165 | 9 | 14.0 | 8.0 | 3 | 158 | 15˚ | 10 | 2 | 165 | M8x1.25 | 1.71 | 1.53 |

| 27 | 48210-135XV | 210 | 208 | 135 | 48 | 13 | 21.71 | 16.5 | 40 | 12 | 165 | 9 | 14.0 | 8.0 | 3 | 158 | 15˚ | 10 | 2 | 165 | M8x1.25 | 1.71 | 1.53 |

| 28 | 24250-160XV | 250 | 248 | 160 | 24 | 11 | 21.42 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10.0 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.42 | 1.27 |

| 29 | 40250-160XV | 250 | 248 | 160 | 40 | 13 | 21.71 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10.0 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.71 | 1.53 |

| 30 | 48250-160XV | 250 | 248 | 160 | 48 | 11 | 21.42 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10.0 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.42 | 1.27 |

| 31 | 60250-160XV | 250 | 248 | 160 | 60 | 9 | 21.63 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10.0 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.63 | 1.45 |

| 32 | 72250-160XV | 250 | 248 | 160 | 72 | 11 | 21.42 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10.0 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.42 | 1.27 |

| 33 | 360250-160XV | 250 | 248 | 160 | 360 | 7 | 20.30 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10.0 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.5 | 0.30 | 0.27 |

| 34 | 48280-190XV | 280 | 278 | 190 | 48 | 13 | 21.59 | 16.5 | 40 | 8 | 222 | 13 | 20.0 | 12.0 | 3 | 222 | 22.5˚ | 10 | 2 | 222 | M10x1.50 | 1.59 | 1.42 |

| 35 | 60280-190XV | 280 | 278 | 190 | 60 | 11 | 26.82 | 21.5 | 50 | 10 | 224 | 11 | 17.5 | 10.0 | 3 | 224 | 18˚ | 10 | 2 | 224 | M10x1.50 | 1.82 | 1.62 |

| 36 | 72280-190XV | 280 | 278 | 190 | 72 | 11 | 21.42 | 16.5 | 40 | 8 | 222 | 13 | 20.0 | 12.0 | 3 | 222 | 22.5˚ | 10 | 2 | 222 | M10x1.50 | 1.42 | 1.27 |

| 37 | 360280-190XV | 280 | 278 | 190 | 360 | 8 | 20.35 | 16.5 | 40 | 8 | 222 | 13 | 20.0 | 12.0 | 3 | 222 | 22.5˚ | 10 | 2 | 222 | M10x1.5 | 0.35 | 0.30 |

| 38 | 48320-210XV | 320 | 318 | 210 | 48 | 11 | 30.82 | 25.5 | 58 | 12 | 258 | 13 | 20.0 | 12.0 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 1.82 | 1.62 |

| 39 | 60320-210XV | 320 | 318 | 210 | 60 | 11 | 30.46 | 25.5 | 58 | 10 | 258 | 13 | 20.0 | 12.0 | 3 | 258 | 18˚ | 12 | 4 | 258 | M12x1.75 | 1.46 | 1.30 |

| 40 | 72320-210XV | 320 | 318 | 210 | 72 | 11 | 30.74 | 25.5 | 58 | 12 | 258 | 13 | 20.0 | 12.0 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 1.74 | 1.55 |

| 41 | 360320-210XV | 320 | 316 | 210 | 360 | 8 | 29.35 | 25.5 | 58 | 12 | 258 | 13 | 20.0 | 12.0 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 0.35 | 0.30 |

| 42 | 60360-250XV | 360 | 358 | 250 | 60 | 13 | 30.64 | 26.0 | 58 | 12 | 300 | 13 | 20.0 | 12.0 | 3 | 300 | 15˚ | 12 | 4 | 300 | M12x1.75 | 1.64 | 1.46 |

| 43 | 72360-250XV | 360 | 358 | 250 | 72 | 11 | 30.37 | 26.0 | 58 | 12 | 300 | 13 | 20.0 | 12.0 | 3 | 300 | 15˚ | 12 | 4 | 300 | M12x1.75 | 1.37 | 1.22 |

| 44 | 360360-250XV | 360 | 358 | 250 | 360 | 10 | 29.39 | 26.0 | 58 | 12 | 300 | 13 | 20.0 | 12.0 | 3 | 300 | 15˚ | 12 | 4 | 300 | M12x1.75 | 0.39 | 0.35 |

| 45 | 48400-280XV | 400 | 398 | 280 | 48 | 13 | 31.52 | 26.0 | 60 | 12 | 335 | 13 | 20.0 | 12.0 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 1.52 | 1.36 |

| 46 | 60400-280XV | 400 | 398 | 280 | 60 | 15 | 31.82 | 26.0 | 60 | 12 | 335 | 13 | 20.0 | 12.0 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 1.82 | 1.62 |

| 47 | 72400-280XV | 400 | 398 | 280 | 72 | 13 | 31.52 | 26.0 | 60 | 12 | 335 | 13 | 20.0 | 12.0 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 1.52 | 1.36 |

| 48 | 360400-280XV | 400 | 398 | 280 | 360 | 13 | 30.45 | 26.0 | 60 | 12 | 335 | 13 | 20.0 | 12.0 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 0.45 | 0.39 |

| 49 | 72420-320XV | 420 | 418 | 320 | 72 | 13 | 31.59 | 26.0 | 60 | 12 | 360 | 13 | 20.0 | 12.0 | 3 | 360 | 15˚ | 12 | 4 | 360 | M12x1.75 | 1.59 | 1.42 |

| 50 | 360420-320XV | 420 | 418 | 320 | 360 | 13 | 30.45 | 26.0 | 60 | 12 | 360 | 13 | 20.0 | 12.0 | 3 | 360 | 15˚ | 12 | 4 | 360 | M12x1.75 | 0.45 | 0.39 |

| 51 | 72450-340XV | 450 | 448 | 340 | 72 | 15 | 31.71 | 26.0 | 60 | 12 | 387 | 13 | 20.0 | 12.0 | 3 | 387 | 15˚ | 12 | 4 | 387 | M12x1.75 | 1.71 | 1.53 |

| 52 | 360450-340XV | 450 | 448 | 340 | 360 | 15 | 30.49 | 26.0 | 60 | 12 | 387 | 13 | 20.0 | 12.0 | 3 | 387 | 15˚ | 12 | 4 | 387 | M12x1.75 | 0.49 | 0.42 |

| 53 | 48520-415XV | 520 | 518 | 415 | 48 | 15 | 31.97 | 26.0 | 60 | 12 | 450 | 13 | 20.0 | 12.0 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.97 | 1.76 |

| 54 | 72520-415XV | 520 | 518 | 415 | 72 | 15 | 31.97 | 26.0 | 60 | 12 | 450 | 13 | 20.0 | 12.0 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.97 | 1.76 |

| 55 | 360520-415XV | 520 | 518 | 415 | 360 | 15 | 30.57 | 26.0 | 60 | 12 | 450 | 13 | 20.0 | 12.0 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 0.57 | 0.49 |

| 56 | 60600-480XV | 600 | 598 | 480 | 60 | 15 | 36.95 | 29.0 | 70 | 12 | 530 | 17 | 26.0 | 16.0 | 3 | 530 | 15˚ | 12 | 4 | 530 | M12x1.75 | 1.95 | 1.74 |

| 57 | 72600-480XV | 600 | 598 | 480 | 72 | 19 | 37.28 | 29.0 | 70 | 12 | 530 | 17 | 26.0 | 16.0 | 3 | 530 | 15˚ | 12 | 4 | 530 | M12x1.75 | 2.28 | 2.04 |

| 58 | 360600-480XV | 600 | 598 | 480 | 360 | 15 | 35.66 | 29.0 | 70 | 12 | 530 | 17 | 26.0 | 16.0 | 3 | 530 | 15˚ | 14 | 4 | 530 | M12x1.75 | 0.66 | 0.57 |

| 59 | 72700-560XV | 700 | 698 | 560 | 72 | 19 | 36.70 | 29.0 | 70 | 12 | 610 | 17 | 26.0 | 16.0 | 3 | 610 | 15˚ | 14 | 4 | 610 | M12x1.75 | 1.70 | 1.50 |

| 60 | 360700-560XV | 700 | 698 | 560 | 360 | 19 | 35.67 | 29.0 | 70 | 12 | 610 | 17 | 26.0 | 16.0 | 3 | 610 | 15˚ | 14 | 4 | 610 | M12x1.75 | 0.67 | 0.58 |

| 61 | 72800-660XV | 800 | 798 | 660 | 72 | 19 | 39.20 | 32.0 | 75 | 18 | 710 | 17 | 26.0 | 16.0 | 3 | 710 | 10˚ | 14 | 4 | 710 | M12x1.75 | 1.70 | 1.50 |

| 62 | 360800-660XV | 800 | 798 | 660 | 360 | 19 | 38.26 | 32.0 | 75 | 18 | 710 | 17 | 26.0 | 16.0 | 3 | 710 | 10˚ | 14 | 4 | 710 | M12x1.75 | 0.76 | 0.68 |

| 63 | 72900-740XV | 900 | 898 | 740 | 72 | 21 | 41.70 | 34.5 | 80 | 18 | 800 | 17 | 26.0 | 16.0 | 3 | 800 | 10˚ | 14 | 4 | 800 | M12x1.75 | 1.70 | 1.50 |

| 64 | 360900-740XV | 900 | 898 | 740 | 360 | 21 | 40.98 | 34.5 | 80 | 18 | 800 | 17 | 26.0 | 16.0 | 3 | 800 | 10˚ | 14 | 4 | 800 | M12x1.75 | 0.98 | 0.88 |

| 65 | 721000-830XV | 1000 | 998 | 830 | 72 | 22 | 61.70 | 54.5 | 120 | 18 | 900 | 17 | 26.0 | 16.0 | 4 | 900 | 10˚ | - | 4 | 900 | M12x1.75 | 1.70 | 1.50 |

| 66 | 3601000-830XV | 1000 | 998 | 830 | 360 | 22 | 60.95 | 54.5 | 120 | 18 | 900 | 17 | 26.0 | 16.0 | 4 | 900 | 10˚ | - | 4 | 900 | M12x1.75 | 0.95 | 0.82 |

| 67 | 721100-900XV | 1100 | 1098 | 900 | 72 | 22 | 66.70 | 59.5 | 130 | 20 | 980 | 21 | 32.0 | 20.0 | 4 | 980 | 9˚ | - | 4 | 980 | M16x2.00 | 1.70 | 1.50 |

| 68 | 3601100-900XV | 1100 | 1098 | 900 | 360 | 22 | 66.05 | 59.5 | 130 | 20 | 980 | 21 | 32.0 | 20.0 | 4 | 980 | 9˚ | - | 4 | 980 | M16x2.00 | 1.05 | 0.91 |

| 69 | 721200-1000XV | 1200 | 1198 | 1000 | 72 | 22 | 71.70 | 64.5 | 140 | 20 | 1,080 | 21 | 32.0 | 20.0 | 4 | 1,080 | 9˚ | - | 4 | 1,080 | M16x2.00 | 1.70 | 1.50 |

| 70 | 3601200-1000XV | 1200 | 1198 | 1000 | 360 | 22 | 71.14 | 64.5 | 140 | 20 | 1,080 | 21 | 32.0 | 20.0 | 4 | 1,080 | 9˚ | - | 4 | 1,080 | M16x2.00 | 1.14 | 0.98 |

| 71 | 721300-1100XV | 1300 | 1298 | 1100 | 72 | 22 | 76.70 | 69.5 | 150 | 24 | 1,170 | 21 | 32.0 | 20.0 | 4 | 1,170 | 7.5˚ | - | 4 | 1,170 | M16x2.00 | 1.70 | 1.50 |

| 72 | 3601300-1100XV | 1300 | 1298 | 1100 | 360 | 22 | 76.24 | 69.5 | 150 | 24 | 1,170 | 21 | 32.0 | 20.0 | 4 | 1,170 | 7.5˚ | - | 4 | 1,170 | M16x2.00 | 1.24 | 1.10 |

| No. | Model No | Division | Out side dia meter |

Out side dia meter of Teeth |

Inside dia meter |

Num ber of teeth |

Teeth width | Tooth top from back face | Boss from back face | Stacking distance | Fixed bolt hole | Positioning pin hole | Withdraw bolt hole | Adden dum |

Allowable Misalign -ment |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of hole |

PCD | Hole diameter | Spot facing hole | Number of pin hole | PCD | Angle of hole | Hole diameter | Number of bolt hole |

PCD | Tap diameter |

||||||||||||||

| Diameter | Depth | |||||||||||||||||||||||

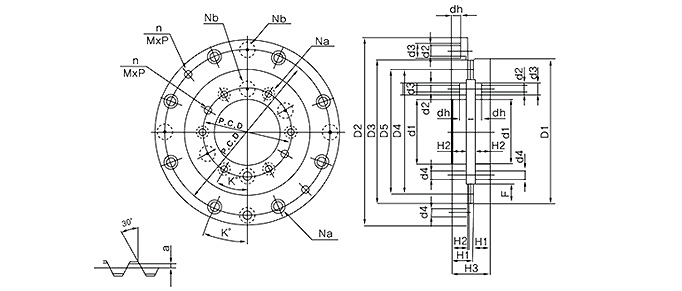

| D1 | D2 | d1 | N | F | H1 | H2 | H3 | Na | P.C.D | d2 | d3 | dh | Nb | P.C.D | K˚ | d4 | n | P.C.D | MxP | a | ±A | |||

| 101 | 024110-040 | V1, X | 110 | - | 40 | 24 | 14 | 16.75 | 11.5 | 30 | 6 | 60 | 6.6 | 11 | 6 | 3 | 60 | 30˚ | 8 | 2 | 60 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 170 | - | 24 | - | 16.75 | 11.5 | 30 | 8 | 140 | M10 | 14 | 8.5 | 3 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.75 | 1.55 | ||

| 102 | 030110-040 | V1, X | 110 | - | 40 | 30 | 14 | 16.4 | 11.5 | 30 | 6 | 60 | 6.6 | 11 | 6 | 1 | 60 | 30˚ | 8 | 2 | 60 | M8x1.25 | 1.4 | 1.26 |

| V0 | - | 170 | - | 30 | - | 16.4 | 11.5 | 30 | 8 | 140 | M10 | 14 | 8.5 | 1 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.4 | 1.26 | ||

| 103 | 024135-060 | V1, X | 135 | - | 60 | 24 | 18 | 18.75 | 13.5 | 34 | 6 | 80 | 6.6 | 11 | 6 | 3 | 80 | 30˚ | 8 | 2 | 80 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 175 | - | 24 | - | 18.75 | 13.5 | 34 | 8 | 150 | M10 | 14 | 8.5 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 1.75 | 1.55 | ||

| 104 | 030135-060 | V1, X | 135 | - | 60 | 30 | 18 | 18.75 | 13.5 | 34 | 6 | 80 | 6.6 | 11 | 6.5 | 1 | 80 | 30˚ | 8 | 2 | 80 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 175 | - | 30 | - | 18.75 | 13.5 | 34 | 8 | 150 | M10 | 14 | 8.5 | 3 | 150 | 22.5˚ | 8 | 2 | 150 | M8x1.25 | 1.75 | 1.55 | ||

| 105 | 024165-080 | V1, X | 165 | - | 80 | 24 | 20 | 20.75 | 15.5 | 38 | 6 | 100 | 6.6 | 11 | 6 | 3 | 100 | 30˚ | 8 | 2 | 100 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 220 | - | 24 | - | 20.75 | 15.5 | 38 | 8 | 195 | M12 | 17.5 | 10.5 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.75 | 1.55 | ||

| 106 | 030165-080 | V1, X | 165 | - | 80 | 30 | 20 | 20.75 | 15.5 | 38 | 6 | 100 | 6.6 | 11 | 6 | 1 | 100 | 30˚ | 8 | 2 | 100 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 220 | - | 30 | - | 20.75 | 15.5 | 38 | 8 | 195 | M12 | 17.5 | 10.5 | 3 | 195 | 22.5˚ | 10 | 4 | 195 | M10x1.50 | 1.75 | 1.55 | ||

| 107 | 024200-120 | V1, X | 200 | - | 120 | 24 | 20 | 21.75 | 16.5 | 40 | 8 | 140 | 9 | 14 | 8 | 3 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 255 | - | 24 | - | 21.75 | 16.5 | 40 | 10 | 224 | M12 | 17.5 | 10.5 | 3 | 224 | 18˚ | 10 | 2 | 224 | M10x1.50 | 1.75 | 1.55 | ||

| 108 | 030200-120 | V1, X | 200 | - | 120 | 30 | 20 | 21.75 | 16.5 | 40 | 8 | 140 | 9 | 14 | 8 | 3 | 140 | 22.5˚ | 8 | 2 | 140 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 255 | - | 30 | - | 21.75 | 16.5 | 40 | 10 | 224 | M12 | 17.5 | 10.5 | 3 | 224 | 18˚ | 10 | 2 | 224 | M10x1.50 | 1.75 | 1.55 | ||

| 109 | 024230-135 | V1, X | 230 | - | 135 | 24 | 22 | 21.75 | 16.5 | 40 | 12 | 165 | 9 | 14 | 8 | 3 | 165 | 15˚ | 10 | 2 | 165 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 290 | - | 24 | - | 21.75 | 16.5 | 40 | 12 | 258 | M12 | 17.5 | 10.5 | 3 | 258 | 15˚ | 12 | 2 | 258 | M12x1.75 | 1.75 | 1.55 | ||

| 110 | 030230-135 | V1, X | 230 | - | 135 | 30 | 22 | 21.75 | 16.5 | 40 | 12 | 165 | 9 | 14 | 8 | 3 | 165 | 15˚ | 10 | 2 | 165 | M8x1.25 | 1.75 | 1.55 |

| V0 | - | 290 | - | 30 | - | 21.75 | 16.5 | 40 | 12 | 258 | M12 | 17.5 | 10.5 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 1.75 | 1.55 | ||

| 111 | 0360250-180 | V1, X | 250 | - | 180 | 360 | 8 | 20.2 | 18 | 40 | 12 | 205 | 11 | 17.5 | 10 | 3 | 205 | 15˚ | 10 | 2 | 205 | M10x1.5 | 0.2 | 0.17 |

| V0 | - | 300 | - | 360 | 8 | 20.2 | 18 | 40 | 12 | 270 | M12 | 17.5 | 10.5 | 3 | 270 | 15˚ | 12 | 4 | 270 | M12x1.75 | 0.2 | 0.17 | ||

| 112 | 024270-160 | V1, X | 270 | - | 160 | 24 | 24 | 21.75 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.75 | 1.55 |

| V0 | - | 330 | - | 24 | - | 21.75 | 16.5 | 40 | 12 | 300 | M14 | 20 | 12.5 | 3 | 300 | 15˚ | 12 | 4 | 300 | M12x1.75 | 1.75 | 1.55 | ||

| 113 | 030170-160 | V1, X | 270 | - | 160 | 30 | 24 | 21.75 | 16.5 | 40 | 8 | 195 | 11 | 17.5 | 10 | 3 | 195 | 22.5˚ | 10 | 2 | 195 | M10x1.50 | 1.75 | 1.55 |

| V0 | - | 330 | - | 30 | - | 21.75 | 16.5 | 40 | 12 | 300 | M14 | 20 | 12.5 | 3 | 300 | 15˚ | 12 | 4 | 300 | M12x1.75 | 1.75 | 1.55 | ||

| 114 | 0360270-160 | V1, X | 270 | - | 160 | 360 | 10 | 20.2 | 18 | 40 | 8 | 220 | 11 | 17.5 | 10 | 3 | 220 | 22.5˚ | 10 | 2 | 220 | M10x1.5 | 0.2 | 0.17 |

| V0 | - | 330 | - | 360 | 10 | 20.2 | 18 | 40 | 12 | 300 | M14 | 20 | 12.5 | 3 | 300 | 15˚ | 12 | 4 | 300 | M12x1.75 | 0.2 | 0.17 | ||

| 115 | 048335-220 | V1, X | 335 | - | 220 | 48 | 24 | 25.75 | 18.5 | 48 | 12 | 258 | 13 | 20 | 12 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.7 | 1.75 | 1.55 |

| V0 | - | 400 | - | 48 | - | 25.75 | 18.5 | 48 | 12 | 360 | 13 | 20 | 12.5 | 3 | 360 | 15˚ | 12 | 4 | 360 | M12x1.75 | 1.75 | 1.55 | ||

| 116 | 060335-220 | V1, X | 335 | - | 220 | 60 | 24 | 25.75 | 18.5 | 48 | 12 | 258 | 13 | 20 | 12 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 400 | - | 60 | - | 25.75 | 18.5 | 48 | 12 | 360 | 13 | 20 | 12.5 | 3 | 360 | 15˚ | 12 | 4 | 360 | M12x1.75 | 1.75 | 1.55 | ||

| 117 | 072335-220 | V1, X | 335 | - | 220 | 72 | 24 | 25.75 | 18.5 | 48 | 12 | 258 | 13 | 20 | 12 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 400 | - | 72 | - | 25.75 | 18.5 | 48 | 12 | 360 | 13 | 20 | 12.5 | 3 | 360 | 15˚ | 12 | 4 | 360 | M12x1.75 | 1.75 | 1.55 | ||

| 118 | 0360335-220 | V1, X | 335 | - | 220 | 360 | 14 | 24.32 | 18.5 | 48 | 12 | 258 | 13 | 20 | 12 | 3 | 258 | 15˚ | 12 | 4 | 258 | M12x1.75 | 0.32 | 0.27 |

| V0 | - | 400 | - | 360 | - | 24.32 | 18.5 | 48 | 12 | 360 | 13 | 20 | 12.5 | 3 | 360 | 15˚ | 12 | 4 | 360 | M12x1.75 | 0.32 | 0.27 | ||

| 119 | 048425-300 | V1, X | 425 | - | 300 | 48 | 28 | 26.75 | 19.5 | 50 | 12 | 335 | 13 | 20 | 12 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 482 | - | 48 | - | 26.75 | 19.5 | 50 | 12 | 450 | 13 | 20 | 12.5 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.75 | 1.55 | ||

| 120 | 060425-300 | V1, X | 425 | - | 300 | 60 | 28 | 26.75 | 19.5 | 50 | 12 | 335 | 13 | 20 | 12 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 482 | - | 60 | - | 26.75 | 19.5 | 50 | 12 | 450 | 13 | 20 | 12.5 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.75 | 1.55 | ||

| 121 | 072425-300 | V1, X | 425 | - | 300 | 72 | 28 | 26.75 | 19.5 | 50 | 12 | 335 | 13 | 20 | 12 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 482 | - | 72 | - | 26.75 | 19.5 | 50 | 12 | 450 | 13 | 20 | 12.5 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.75 | 1.55 | ||

| 122 | 0360425-300 | V1, X | 425 | - | 300 | 360 | 20 | 25.42 | 19.5 | 50 | 12 | 335 | 13 | 20 | 12 | 3 | 335 | 15˚ | 12 | 4 | 335 | M12x1.75 | 0.42 | 0.37 | V0 | - | 482 | - | 360 | - | 25.42 | 19.5 | 50 | 12 | 450 | 13 | 20 | 12.5 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 0.42 | 0.37 |

| 123 | 048540-415 | V1, X | 540 | - | 415 | 48 | 32 | 29.25 | 22.5 | 55 | 12 | 450 | 13 | 20 | 12 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 604 | - | 48 | - | 29.25 | 22.5 | 55 | 12 | 570 | 17 | 26 | 16.5 | 3 | 570 | 15˚ | 12 | 4 | 570 | M12x1.75 | 1.75 | 1.55 | ||

| 124 | 060540-415 | V1, X | 540 | - | 415 | 60 | 32 | 29.25 | 22.5 | 55 | 12 | 450 | 13 | 20 | 12 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 604 | - | 60 | - | 29.25 | 22.5 | 55 | 12 | 570 | 17 | 26 | 16.5 | 3 | 570 | 15˚ | 12 | 4 | 570 | M12x1.75 | 1.75 | 1.55 | ||

| 125 | 072540-415 | V1, X | 540 | - | 415 | 72 | 32 | 29.25 | 22.5 | 55 | 12 | 450 | 13 | 20 | 12 | 3 | 450 | 15˚ | 12 | 4 | 450 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 604 | - | 72 | - | 29.25 | 22.5 | 55 | 12 | 570 | 17 | 26 | 16.5 | 3 | 570 | 15˚ | 12 | 4 | 570 | M12x1.75 | 1.75 | 1.55 | ||

| 126 | 0360540-415 | V1, X | 540 | - | 415 | 360 | 24 | 28.06 | 22.5 | 55 | 12 | 450 | 13 | 20 | 12 | 3 | 450 | 15˚ | 12 | 2 | 450 | M12x1.75 | 0.56 | 0.5 |

| V0 | - | 604 | - | 360 | - | 28.06 | 22.5 | 55 | 12 | 570 | 17 | 26 | 16.5 | 3 | 570 | 15˚ | 12 | 2 | 570 | M12x1.75 | 0.56 | 0.5 | ||

| 127 | 072630-490 | V1, X | 630 | - | 490 | 72 | 32 | 31.75 | 24.5 | 60 | 12 | 530 | 17 | 26 | 14 | 3 | 530 | 15˚ | 12 | 4 | 530 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 700 | - | 72 | - | 31.75 | 24.5 | 60 | 18 | 660 | 17 | 26 | 16.5 | 3 | 660 | 10˚ | 12 | 4 | 660 | M12x1.75 | 1.75 | 1.55 | ||

| 128 | 0360630-490 | V1, X | 630 | - | 490 | 360 | 28 | 30.67 | 24.5 | 60 | 12 | 530 | 17 | 26 | 14 | 3 | 530 | 15˚ | 12 | 4 | 530 | M12x1.75 | 0.67 | 0.58 |

| V0 | - | 700 | - | 360 | - | 30.67 | 24.5 | 60 | 18 | 660 | 17 | 26 | 16.5 | 3 | 660 | 10˚ | 12 | 4 | 660 | M12x1.75 | 0.67 | 0.58 | ||

| 129 | 072820-670 | V1, X | 820 | - | 670 | 72 | 40 | 39.25 | 28.5 | 75 | 18 | 710 | 17 | 26 | 14 | 3 | 710 | 10˚ | 14 | 4 | 710 | M12x1.75 | 1.75 | 1.55 |

| V0 | - | 890 | - | 72 | - | 39.25 | 28.5 | 75 | 18 | 850 | 17 | 26 | 16.5 | 3 | 850 | 10˚ | 14 | 4 | 850 | M12x1.75 | 1.75 | 1.55 | ||